Maintenance Debt in Swedish Power Grids – Why It’s Growing and What It Means

February 2026

Sweden's power grid is in the midst of a historic transformation. Across the country, grid operators are raising their fees to finance investments in infrastructure capable of handling both increased demand and greater strain from extreme weather.

Research from Lund University shows that if power grids are not adapted to extreme climate events and continued urbanisation, the reliability of electricity supply could decrease by up to 30 percent. To ensure that cities can handle climate-related strain during the energy transition, additional investments of 20–60 percent may be required.

Extreme heat puts pressure on transformer stations. Cold snaps cause electricity consumption to spike. Storms and heavy rainfall strike infrastructure that was built for a different climate.

Many of the largest power outages are already caused by weather-related events – and they are becoming both more frequent and harder to predict. To maintain stable electricity supply, maintenance and monitoring must become as smart as the grid itself.

A robust power grid is built not just with steel and cables, but with data. By connecting both new and existing infrastructure, grid owners gain a clearer picture of the system's actual status in real time. This makes it possible to detect problems early, before they lead to downtime – while also providing confidence that the grid can withstand the stresses it faces. Maintenance can be planned under safe conditions rather than requiring technicians to respond during an ongoing storm. Automation also reduces the need for physical presence during high-risk work tasks.

In short: From emergency response to planned interventions, based on actual asset conditions.

At a time when supply security and sustainability reporting are high on the agenda, intelligent maintenance becomes not just a technical solution, but a strategic asset.

A concrete example can be found in the management of oil containment bunds at transformer stations. These pits are designed to prevent oil from leaking into the environment in the event of a transformer failure. However, during heavy rainfall they can quickly fill with rainwater and therefore need to be drained. If the water is not drained in time and the level rises above the critical threshold, there is a risk of oil spreading into the surrounding environment.

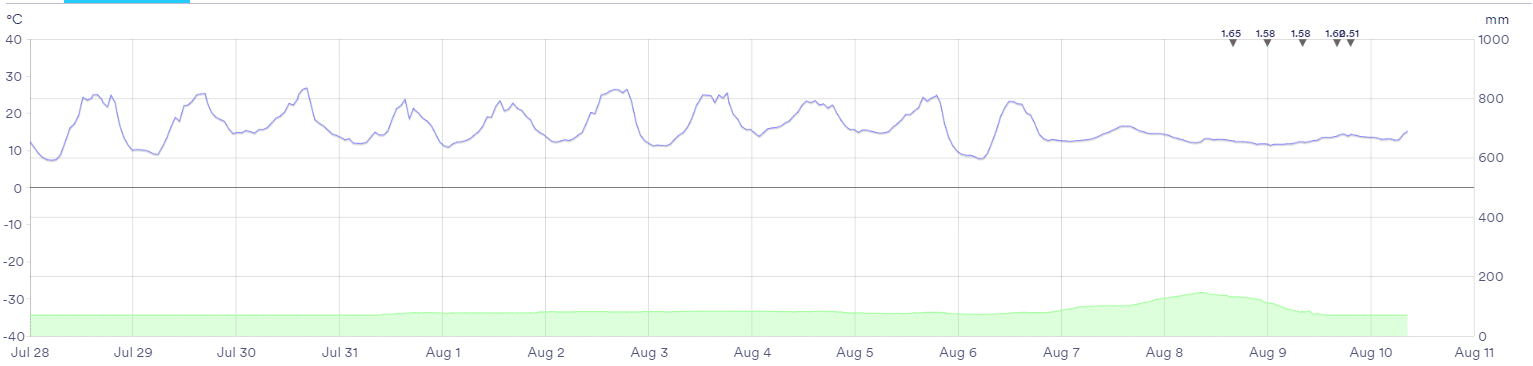

Graph 1. Manual maintenance – risk of flooding

The water level rises rapidly after heavy rain. In less than 24 hours, the level reaches critical limits (red area) and the risk of oil spillage increases.

Graph 2. Automated maintenance – stable operation

With automated drainage and continuous monitoring, the water level remains consistently low (green area). The system responds immediately to changes and ensures the pit has capacity to capture oil in case of leakage.

"The difference between reactive and proactive maintenance is enormous. With remote monitoring and automated drainage, the system acts before the water level becomes critical, and through our pit analysis we also ensure that the pit is watertight. This protects both the environment and means technicians don't have to respond during dangerous weather conditions," says Niklas Wicén, CPO at Gomero.

We cannot prevent all problems, but we can build systems that handle them better. By combining robust infrastructure with digital monitoring, a power grid is created that is both resilient and forward-looking.

Want to learn more about how predictive maintenance can strengthen your power grid? Contact us and we'll explain how digital solutions contribute to a more sustainable and reliable energy system.